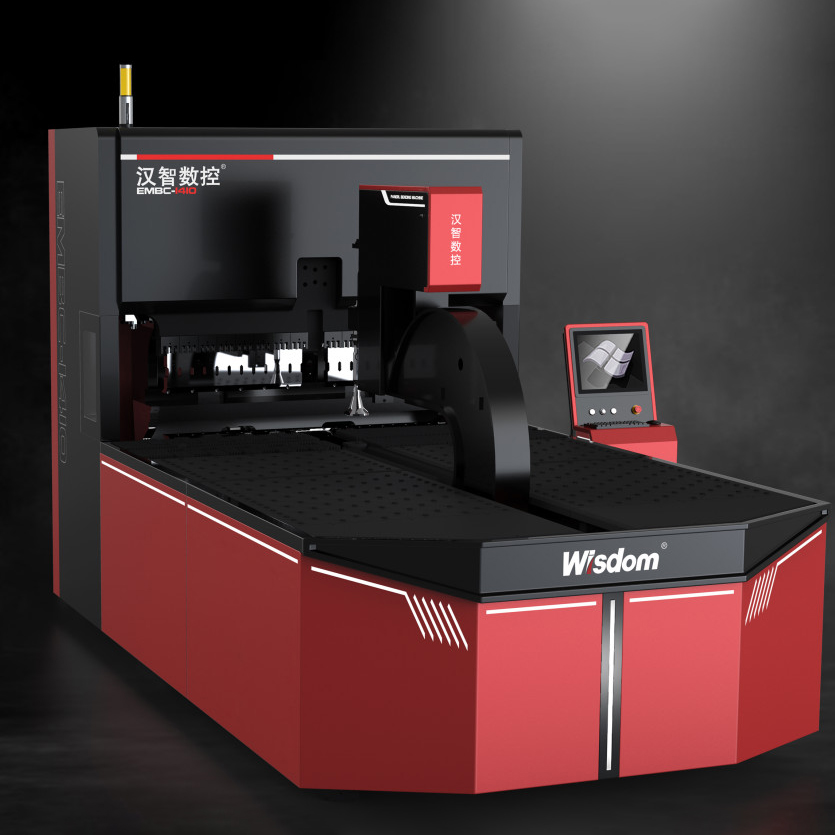

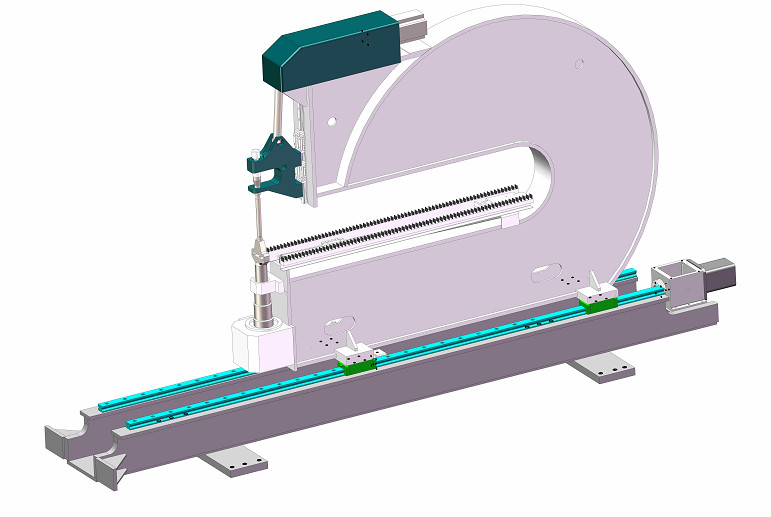

Semi-automatic vaj huam sib luag Bender EMBC 1402

cov khoom specification

| Tsis muaj. | Lub npe | Parameter | Chav tsev |

| 1 | Max. Ntev | 1400 | mm |

| 2 | Max. dav | 1400 | mm |

| 3 | Min.Khoov ntev | 200 | mm |

| 4 | Min.bending dav | 260 | mm |

| 5 | Max.bending thickness (MS, UTS410N/mm²) | 1 | mm |

| 6 | Min.bending thickness (MS, UTS410N / mm²) | 0.5 | mm |

| 7 | Max.bending qhov siab | 170 | mm |

| 8 | Qhov ntev hloov hom ntawm sab sauv xovxwm phau ntawv | ||

| 9 | Kev siv hluav taws xob nruab nrab | 2.2 | KW |

| 10 | Qhov hnyav | 15 | T |

Cov yam ntxwv thiab cov qauv tseem ceeb

Hais txog lub tshuab tsim thiab tsim, Hebei Hanzhi CNC Machinery Co., Ltd.Feem ntau tsom rau cov ntsiab lus hauv qab no:

1. Lub tswv yim kev lag luam uas ua raws li kev ua tau zoo thiab txuag tus neeg siv txhua lub nyiaj.

2. Lub tswv yim tsim kev ntseeg siab heev thiab meej.

3. Cov ntaub ntawv zoo raw khoom, yuav khoom thiab cov txheej txheem ua haujlwm zoo.

4. Ntau qhov tseem ceeb ntawm kev siv yooj yim thiab kev saib xyuas thiab kev nyab xeeb.

5. Tsawg tus nqi tu thiab tu nqi hauv tib lub lag luam.

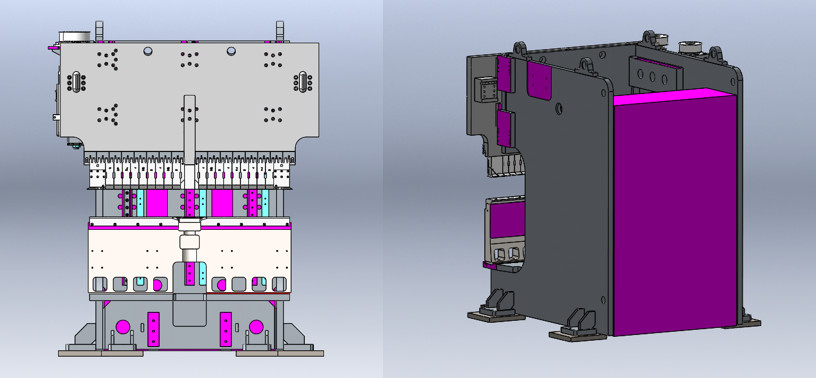

ncej

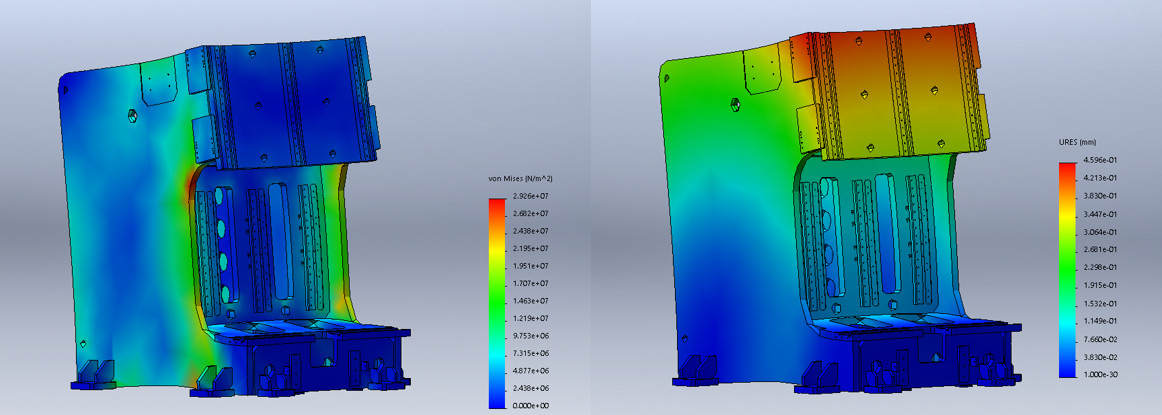

A. Tsim tus qauv 3D finite element: Raws li tus qauv tsim thiab tsim qauv 3D khoom, tus qauv dynamic finite element yog tsim rau kev suav.Tus qauv txiav txim siab txog cov ntsiab lus tseem ceeb ntawm kev sib txuas ntawm kev quab yuam.Cov rog raug xa mus rau cov kabmob los ntawm kev sib txuas thiab tom qab ntawd kev soj ntsuam lub zog ntawm cov kabmob yog nqa tawm.

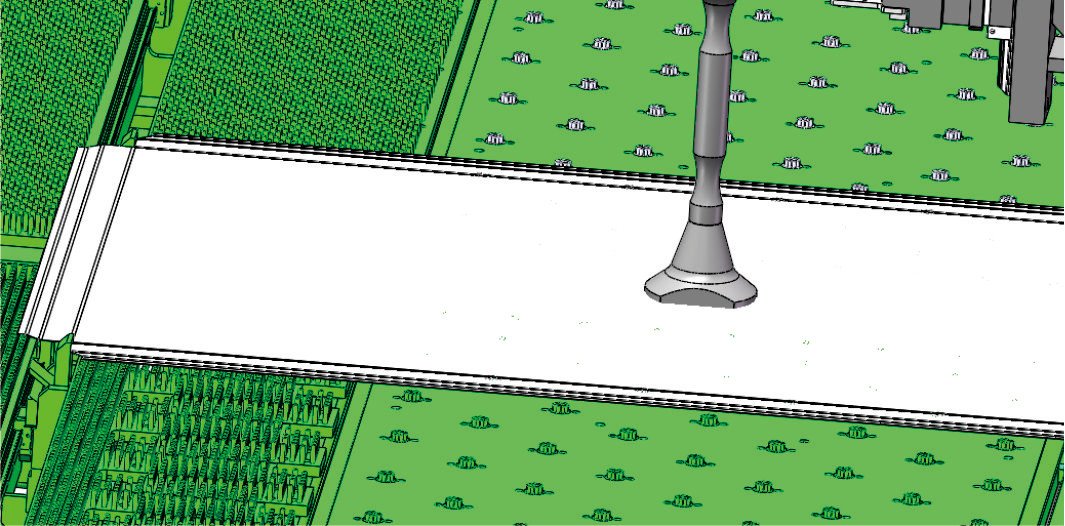

Fig. 1 Vaj Huam Sib Luag bender Finite caij dynamic qauv ntawm lub tshuab tiav

B. Kev txheeb xyuas cov txiaj ntsig zoo li qub: Vim qhov kev ua haujlwm qeeb qeeb, qhov kev soj ntsuam lub zog tuaj yeem raug txo kom muaj teeb meem zoo li qub.Raws li lub phaj compression load thiab khoov load nyob rau hauv ntsug kev taw qhia ntawm lub taub hau cutter, cov kev ntxhov siab thiab deformation tshwm sim tau qhia hauv qab no.Qhov siab tshaj plaws kev ntxhov siab tshwm nyob rau hauv lub caj pas ntawm lub cev nrog lub siab tshaj plaws kev nyuaj siab ntawm 21.2mpa thiab lub siab tshaj plaws deformation tshwm nyob rau hauv lub Upper kawg ntawm lub cev nrog ib tug siab tshaj plaws deformation ntawm 0.30mm.

Raws li cov ntsiab lus txheeb xyuas qhov kawg ntawm tus ncej, Q345 steel raug xaiv los ua cov khoom siv;carbon dioxide shield vuam tau saws;tempering kev kho mob yog nqa tawm kom tshem tawm cov kev ntxhov siab generated los ntawm vuam;yog li ua kom qhov tseeb, ruaj khov thiab siab rigidity ntawm cov cuab yeej siv rau kev ua haujlwm ntev.

Fig. 2 Kev ntxhov siab hloov pauv deformation tsom xam ntawm tus ncej

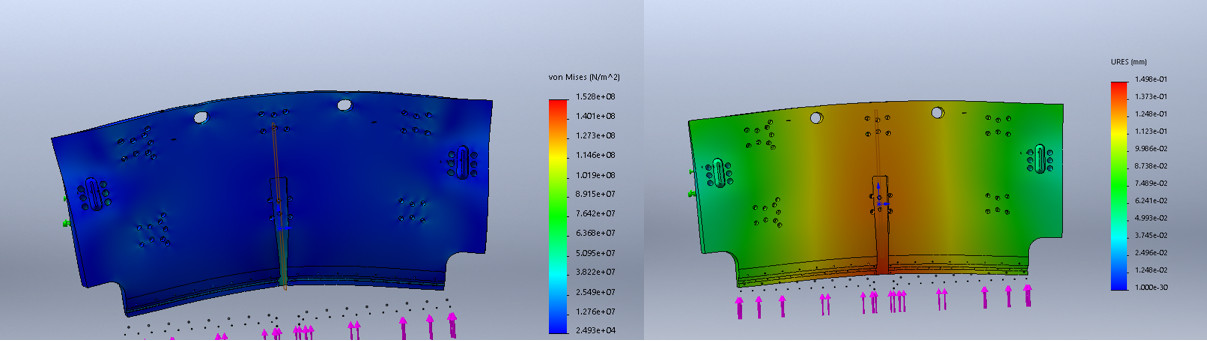

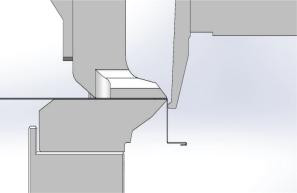

Up ram

Qhov no feem ntau muaj cov slider, siab torque txhuas ntsia hlau, reducer, qhia rail, servo lub cev muaj zog thiab lwm yam.Lub ntsiab tsav yog tswj los ntawm servo lub cev muaj zog thiab kev tswj hom yog servo synchronous tswj, uas tuaj yeem ua kom muaj qhov tseeb ntawm qhov chaw, ceev ceev thiab siab tswj.Lub lubrication ntawm cov hlau lead ntsia hlau thiab cov kev taw qhia rail adopts tsis siv neeg lubrication, thiab cov roj yog 00 #, uas ua kom lub neej kev pab cuam thiab precision ntawm cov hlau lead ntsia hlau thiab qhia rail rau lub sij hawm ntev ua hauj lwm.

Kev soj ntsuam zoo li qub ntawm cov slider sab sauv: qhov kev ntxhov siab hloov lub raum daim duab ntawm lub rooj sab sauv qhia tau hais tias qhov siab tshaj plaws kev ntxhov siab tshwm nyob rau hauv sab sauv, qhov siab tshaj plaws kev ntxhov siab yog 152mpa, qhov siab tshaj plaws deformation tshwm nyob rau hauv qhov kawg ntawm lub rooj sab sauv, qhov siab tshaj plaws deformation. yog 0.15mm

Fig. 3 Kev ntsuam xyuas qhov kev ntxhov siab ntawm cov ram

Raws li cov ntsiab lus txheeb xyuas qhov kawg ntawm cov ram, Q345 steel raug xaiv los ua cov khoom siv;CO2 shielded vuam tau siv;tempering kev kho mob yog nqa tawm kom tshem tawm cov kev ntxhov siab los ntawm vuam;yog li ua kom qhov tseeb, ruaj khov thiab siab rigidity ntawm cov cuab yeej siv rau kev ua haujlwm ntev.

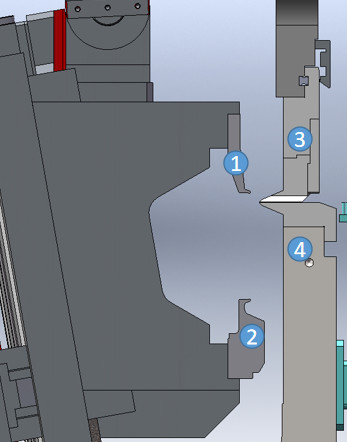

Khoov unit

Lub zog tsav ib feem ntawm lub tshuab khoov yog tsav los ntawm servo lub cev muaj zog yam tsis muaj kev koom tes ntawm hydraulic system, uas muaj qhov zoo ntawm kev txo qis hnav thiab tsim kua muag ntawm cov khoom thiab kev sib kis tau zoo, raws li txoj cai txuag hluav taws xob thiab kev tiv thaiv ib puag ncig. los ntawm lub xeev.

Raws li kev teeb tsa ntawm daim ntawv xov xwm, lub kaw lus cia li xam qhov chaw ntawm lub xovxwm sab sauv riam 3 thiab tswj qhov kev ncua deb ntawm cov xovxwm sab sauv riam 3 thiab qis xovxwm riam 4 txhawm rau txhim kho daim ntawv;Raws li qhov system teeb tsa, txawm tias qhov kev khoov no yog nce lossis nqis, qis xovxwm riam 2 lossis lub xovxwm sab sauv 1 yog tswj kom txav mus sai sai rau txoj haujlwm khoov;Raws li qhov sib txawv ntawm qhov sib txawv, cov riam khoov yog tswj kom txav mus rau hauv txoj haujlwm xam los ntawm patented lub kaum sab xis xam cov mis kom tiav cov dabtsi yog khoov.

Raws li txoj kev sib txawv ntawm kev khoov, tuaj yeem muab faib ua lub kaum sab xis khoov, loj arc dabtsi yog khoov, flattening dabtsi yog khoov, thiab lwm yam, uas lub kaum sab xis khoov tau muab faib ua upward dabtsi yog khoov thiab downward dabtsi yog khoov.

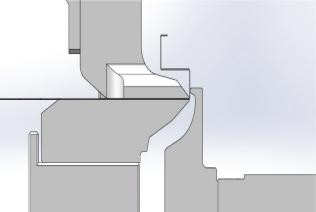

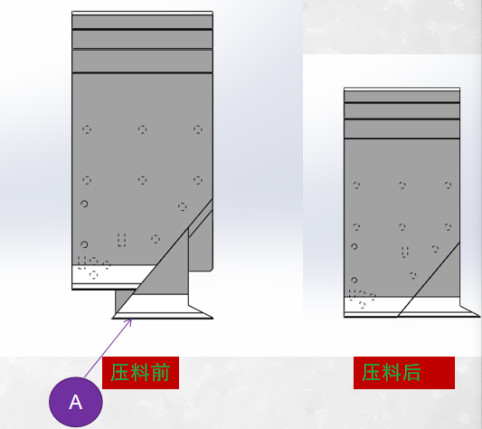

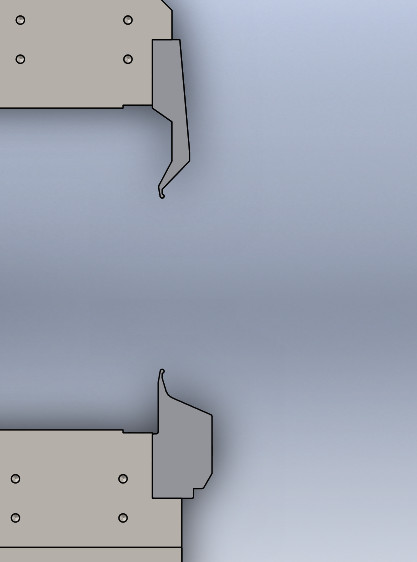

Upper press unit

Fig.6 Upper press unit

Lub tsev xovxwm sab saud: ib feem ntawm tag nrho cov txheej txheem dabtsi yog khoov, EmbC tag nrho servo multilateral dabtsi yog khoov chaw yog nruab nrog ib tug tshwj xeeb sab sauv xovxwm tsev uas yuav tsum tau ntsia thiab manually kho rau txawv phaj ntev.

Txhawm rau ua kom tau raws li qhov yuav tsum tau ua ntawm lub thawv zam kev khoov, peb tau tsim tshwj xeeb zam kev tuag.Ua ntej nias, ib feem ntawm kev zam kev tuag yog nyob rau hauv lub xeev ua ntej nias rau hauv daim duab thiab pib pub mis.Tom qab pub mis, nws yog nyob rau hauv lub xeev tom qab nias hauv daim duab thiab khoov pib.Tom qab khoov, lub sab sauv slider txav.Thaum lub sij hawm txav ntawm lub slider sab sauv, ntu A yuav cia li txav mus rau lub xeev ua ntej nias.Tom qab lub slider sab sauv tau tsiv mus rau qhov chaw teeb tsa, lub zog tom ntej pib.

Fig.7 Khoov lub thawv zam

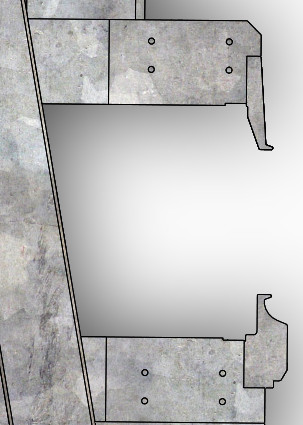

Tool

Cov cuab yeej khoov tau muab faib ua cov cuab yeej khoov sab sauv thiab cov cuab yeej khoov qis.Cov cuab yeej khoov tshwj xeeb tuaj yeem kho raws li qhov sib txawv ntawm cov neeg siv khoom.

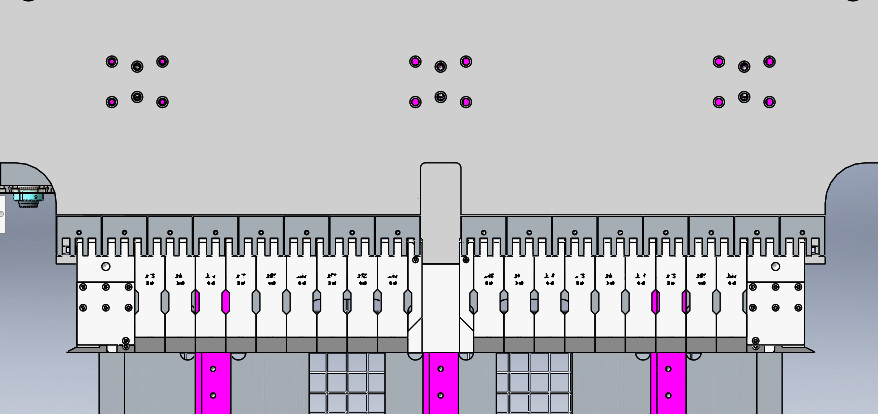

2.Plate feeding unit:

Lub zog, clamping thiab kev sib hloov ntawm cov ntawv hlau yog tswj los ntawm cov neeg hlau 1, lub fixture 2 thiab cov rotating disc 3 raws li.Thaum lub sij hawm tag nrho cov txheej txheem machining, kev pub ntawm cov ntawv hlau yog tswj los ntawm servo motors, ua kom automation thiab ceev positioning, txo lub sij hawm txav thiab nce efficiency.Ua tsaug rau cov qauv kev tsim kho tshiab thiab kev siv tag nrho servo tswj, clamping thiab kev sib hloov ntawm cov ntawv hlau tuaj yeem tswj tau qhov tseeb thoob plaws hauv cov txheej txheem ua haujlwm ntawm ntau qhov chaw khoov.Rau ntau lub workpieces nyuaj, txawm tias polygonal sawv daws yuav, ib qho kev sib hloov tas li ntawm 0.001 tuaj yeem lav.

3.Plate positioning unit:

Lub phaj positioning chav tsev muaj ib tug laug positioning tus pin, ib tug txoj cai positioning tus pin, ib tug pem hauv ntej positioning tus pin thiab rear positioning tus pin;sab laug thiab txoj cai positioning pins muab lub phaj rau sab laug thiab sab xis.Pem hauv ntej positioning tus pin thiab rear positioning tus pin tswj pem hauv ntej thiab nram qab txoj hauj lwm ntawm lub phaj thiab xyuas kom meej tias lub phaj yog sib npaug zos rau lub Upper thiab qis xovxwm riam, uas yog siv los xyuas kom meej qhov chaw ntawm lub phaj.

Lub phaj muab tso rau hauv lub phaj tuaj yeem tso rau ntawm lub phaj thiab tuaj yeem ua tiav ntau qhov kev khoov ntawm ib lub sijhawm, uas ua rau lub sijhawm luv luv ntawm lub voj voog, tswj cov shearing yuam kev ntawm lub phaj ntawm thawj dabtsi yog khoov thiab xyuas kom meej qhov tseeb ntawm dabtsi yog khoov.

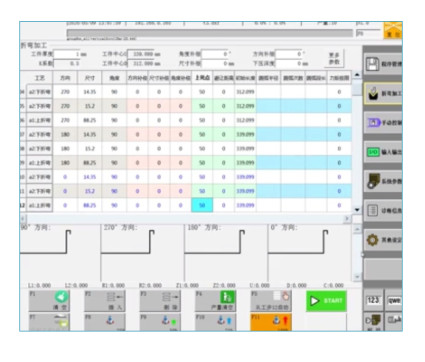

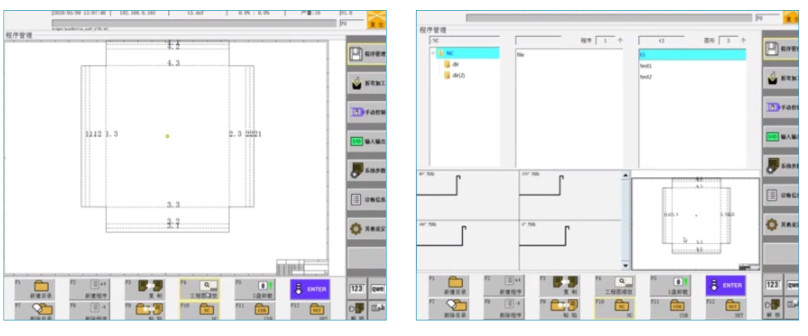

4. CNC system

A: Kev sib koom ua ke tsim CNC tshuab thiab software tuaj yeem siv tau thiab tswj tau sai thiab yooj yim

B: Cov yam ntxwv tseem ceeb.

a).EtherCAT txoj kev tswj tsheb npav nrog kev cuam tshuam tsis zoo

b) Txhawb nqa ncaj qha programming, khoov cov ntaub ntawv rau txhua kauj ruam tuaj yeem nkag rau hauv daim ntawv

c) Kev them nyiaj yug rau nkhaus dabtsi yog khoov

d) Fais fab servo tswj tag nrho

e) Kev them nyiaj yug rau dabtsi yog khoov

f) Kev them nyiaj yug rau ob-seem programming

2D programming muaj nuj nqi, ntshuam 2D DXF cov ntaub ntawv kos duab, tuaj yeem tsim cov txheej txheem khoov, khoov loj, khoov lub kaum sab xis, tig lub kaum sab xis thiab lwm yam ntaub ntawv.Tom qab kev pom zoo, kev khoov tsis siv neeg tuaj yeem ua tiav

Daim ntawv teev npe tseem ceeb

| Tsis muaj. | Lub npe | Hom |

| 1 | Ncej | Kev txawj ntse |

| 2 | Tool | Kev txawj ntse |

| 3 | Khoov unit | Kev txawj ntse |

| 4 | CNC System | Kev txawj ntse |

| 5 | Servo lub cev muaj zog | Kev txawj ntse |

| 6 | Servo tsav tsheb | Kev txawj ntse |

| 7 | Rail | Kev txawj ntse |

| 8 | Ballscrew | Kev txawj ntse |

| 9 | Reducer | Taiwan |

| 10 | Breaker | Schneider |

| 11 | Khawm | Schneider |

| 12 | Hluav taws xob ib feem | Schneider |

| 13 | Kab | Yicu |

| 14 | Qhov sib thooj hloov | Omron |

| 15 | Cov kabmob | SKF/NSK/NWS |

4) Kev tsim, tsim khoom, tshuaj xyuas thiab kev teeb tsa lub tshuab ua tau raws li cov qauv hauv qab no.

1, GB17120-1997

2, Q/321088JWB19-2012

3, GB14349-2011

Daim ntawv teev cov khoom seem thiab cov cuab yeej

| Tsis muaj. | Lub npe | Qt. | Lus ceeb toom |

| 1 | Tool lub thawv | 1 | |

| 2 | Nruab lub ncoo | 8 | |

| 3 | INner hexagon spanner | 1set ib | |

| 4 | Phau ntawv refueling phom | 1 | |

| 5 | CNC system manual | 1 | |

| 6 | qhib spanner | 1 |