Master Precision Thiab Efficiency Nrog CNC Hydraulic Xovxwm Nres

Nta

Siv cov kev ua haujlwm qis qis tuaj yeem ua kom yooj yim Machining ntawm cov haujlwm loj dua.the Dr/ve Device yog muab zais rau hauv qis qis ntawm lub cev tseem ceeb ntawm cov khoom siv, uas txuag qhov chaw nruab nrab ntawm cov ncej, thiab tuaj yeem ua cov haujlwm loj dua.

• siv Central Pressure los tiv thaiv lub zog tsis txaus nyob rau hauv nruab nrab ntawm lub workpiece

Kom Tau Txais Cov Txheej Txheem / ng Ntawm Cov Khoom Siv Siab.

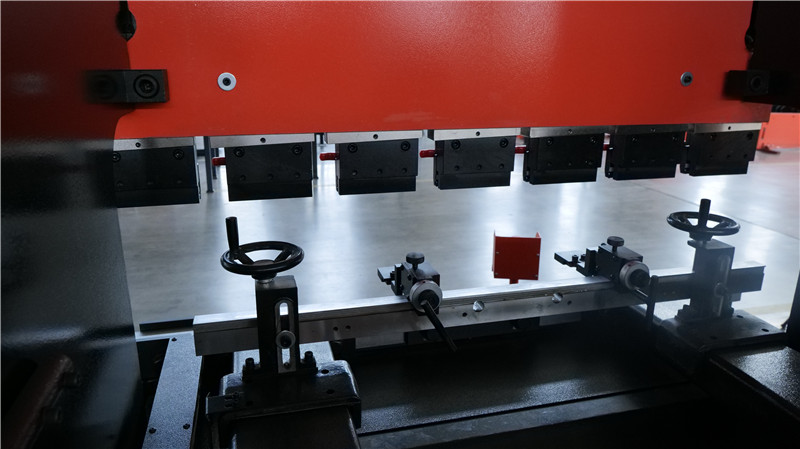

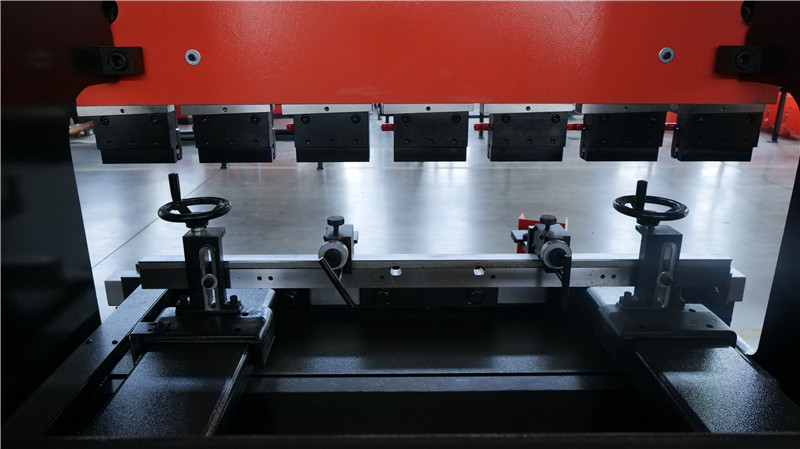

• Thaum lub sij hawm ua, lub rooj ua hauj lwm yog ruaj khov thiab yuav tsis txav.the Roller Guide

Mechanism yog npaj nyob rau hauv pem hauv ntej, rear, sab laug thiab txoj cai taw qhia ntawm lub qis

Worktable, uas tuaj yeem ua rau lub rooj ua haujlwm txav tau yooj yim, thiab tuaj yeem kho tau yooj yim

Qhov sib txawv ntawm Cov Rollers thiab Cov Ntawv Qhia Blocks, thiaj li txo qis Cov Kev Qhia Hnav ntawm Lub Rooj Ua Haujlwm.

• Cov qauv tsim qauv zoo heev khaws cov kev xav tau siab tshaj plaws txawm tias tom qab siv mus ntev.Lub Upper Worktable txais yuav Oblique Thaiv Kho Txoj Kev Rau

Tsis txhob cuam tshuam thiab D / sturbance nyob rau hauv Vuam ncej thiab xyuas kom meej qhov tseeb ntawm kev siv mus sij hawm ntev.Lub Micro-elastic Deformation ntawm Lub Ncej Thaum Ua Tau

Ua zoo-tuned pem hauv ntej ntawm lub workbench.

• Kev txwv qis dua POs/tion ntawm Lub Rooj Sab Nraud yog teem los ntawm kev nyeem tus Encoder Pos/tion.

Nyob rau hauv no Des / gn, sib txawv Lower Limit Pos / tions yuav tsum tau teem raws li txawv khoov-

Ing Lengths, Li no txhim kho qhov khoov efficiency.

• Tsim los nrog Step-by-step Arc Bending Function, Thiab Lub Rov Qab Gauge txav mus rau- Ward ntawm qhov sib npaug.Txhua zaus nws txav mus, ib qho khoov yog tsim, thiab lub siab xav Radian thiab suav nrog lub kaum sab xis yog tsim tom qab ntau zaus ntawm kev khoov.

• Back-rub Avoidance Function, los ntawm kev teeb tsa lub nraub qaum-rub Pos/tion thiab rov qab rub qeeb, Lub workpiece tuaj yeem tiv thaiv kev tsis sib haum xeeb nrog lub nraub qaum nres thaum lub sijhawm

Cov txheej txheem ntawm Machining Lub Workpiece.

• Lub luag haujlwm ntawm suav tag nrho cov khoom khoov.

Mquick Splint yog ib qho yooj yim rau siv thiab tau thov rau patent.

• Thaum lub tshuab qis qis yog nce thiab khoov, lub cev muaj zog tsav lub iav twj tso kua mis rau lub zog tso zis, thiab thaum nws nqis los thiab rov qab los, nws pom tau tias qhov hnyav ntawm lub rooj ua haujlwm / nws tus kheej, thiab lub cev muaj zog idling txuag zog.

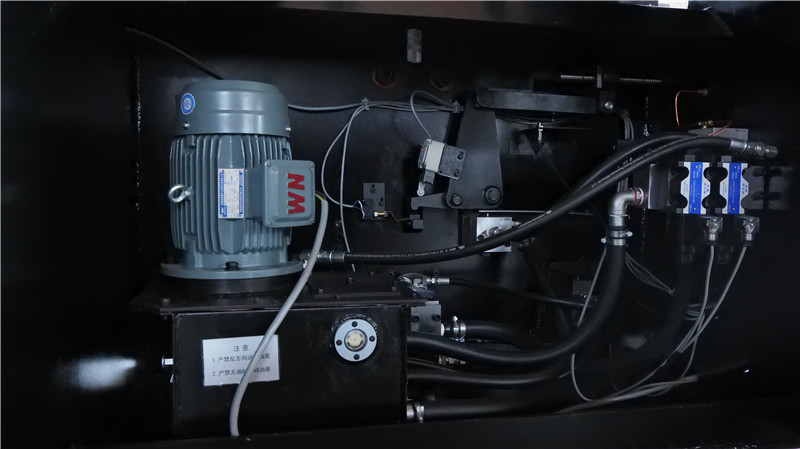

• Wy-100 Txais Cov Roj Circuit Court tsim ntawm Ib Ma / n Roj Lub tog raj kheej thiab ob lub tog raj roj sib txuas, uas tuaj yeem ua tau tiag / ze rau qhov kev ua haujlwm ntawm lub rooj ua haujlwm qis, cov zis tawm tsis zoo, thiab lub rooj ua haujlwm tsis yooj yim deformed.

cov khoom specification

| Qauv thiab ntsig txog kev teeb tsa | ||

| Hom | WY-100 | WY-35 |

| CNC system | Hollysy 5 | Hollysys |

| Servo qhov system | Panasonic/Fuj | Panasonic/Fuj |

| Servo tsheb | Pangsonic/Fuj | panasonic/Fuj |

| Lub zog (KN) | 1000 | 350 |

| Khoov Length (mm) | 3000 | 1400 |

| Up-down stroke (mm) | 100 | 100 |

| caj pas tob (mm) | 405 | 300 |

| No. Lub tog raj kheej | 3 (1 mgin.2Auxiliary) | 1 |

| Kev txav ceev (mm / sec) | 58 | 46 |

| Bending ceev (mm / sec) | 10.8 | 8 |

| Kev nrawm nrawm (mm / sec) | 52 | 40 |

| Upper thiab qis qhov ntev ntawm baffle (mm) | 55-140 : kuv | 55-140 : kuv |

| Tso cai quab yuam ntawm baffle (N) | 100 | 100 |

| Backgauge positioning precision (mm) | ± 0.1 | ± 0.1 |

| X axis stroke (mm) | 430 | 430 |

| X-axis max.Pub ceev (mm / min) | 15 | 15 |

| X-axis repositioning precision (mm) | ± 0.02 hli | ± 0.02 hli |

| Lub cev muaj zog (KW) | 5.5 | 2.2 |

| Qhov hnyav (kg | 6700 ib | 2200 |

| Roj tank peev xwm (L) | 65 | 30 |

nthuav dav

Qhia:

Nyob rau hauv niaj hnub kev lag luam toj roob hauv pes, precision thiab efficiency yog ob yam tseem ceeb uas txiav txim siab qhov kev vam meej ntawm kev tsim khoom.Thaum nws los txog rau hlau fabrication,CNC hydraulic xovxwm nrestau dhau los ua tus txha caj qaum ntawm suav tsis txheeb kev lag luam thoob ntiaj teb.Cov tshuab muaj zog no siv cov thev naus laus zis thiab kev tsim kho tshiab kom xa cov peev txheej zoo dua qub, ua kom cov txiaj ntsig tau meej txhua lub sijhawm.Nyob rau hauv no blog, peb yuav tshawb txog qhov tseem ceeb ntawm CNC hydraulic xovxwm nres thiab yuav ua li cas lawv yog revolutionizing lub metalworking kev lag luam.

Unleash zog thiab precision:

CNC stands rau Computer Numerical Control, thiab thaum siv nrog hydraulic xovxwm nres, nws muab ib tug unrivaled theem ntawm kev tswj thiab precision.Cov tshuab no tau nruab nrog cov khoos phis tawj siab tshaj plaws uas tso cai rau tus neeg teb xov tooj mus rau kev pab cuam thiab tswj ntau yam tsis xws li khoov lub kaum sab xis, qhov nrug ntawm qhov khoov, qhov chaw rov qab, thiab lwm yam. nce productivity.

Yooj yim thiab yoog raws:

Ib qho ntawm qhov zoo tshaj plaws ntawm CNC hydraulic xovxwm nres yog lawv lub peev xwm los lis ntau yam khoom thiab thicknesses.Cov tshuab no tuaj yeem yooj yim tsim cov ntawv hlau rau hauv cov duab nyuaj nrog kev hloov me me, txuag lub sijhawm thiab txo qis sijhawm.Txawm hais tias nws yog stainless hlau, txhuas lossis hlau me, CNC hydraulic xovxwm nres tuaj yeem ua rau lawv txhua tus.Qhov yooj yim muab los ntawm cov tshuab no ua rau cov tuam txhab ua kom tau raws li cov neeg siv khoom sib txawv, yog li txhim kho lawv cov txiaj ntsig kev sib tw.

Zog efficiency:

Raws li kev txhawj xeeb loj hlob txog ib puag ncig kev cuam tshuam ntawm cov txheej txheem kev lag luam, kev siv hluav taws xob tau dhau los ua qhov tseem ceeb rau cov tuam txhab.CNC hydraulic xovxwm nres yog tsim los ua kom muaj zog heev vim tias lawv ua haujlwm siv cov tshuab hydraulic es tsis yog hluav taws xob.Qhov kev tsim no txo qis kev siv hluav taws xob tsawg, txo cov nqi khiav lag luam, thiab ua raws li cov kev coj ua kom ruaj khov.Tsis tas li ntawd, niaj hnub CNC dabtsi yog khoov tshuab yog nruab nrog lub zog-txuag nta xws li tsis siv neeg kaw-tawm thiab standby hom kom zoo dua efficiency.

Nce productivity:

Nyob rau hauv lub ntiaj teb kev sib tw tsim khoom, lub sijhawm yog nyiaj, thiab CNC hydraulic xovxwm nres xa cov txiaj ntsig ntawm qhov nrawm nrawm.Lub peev xwm los ua haujlwm thiab ua haujlwm rov ua haujlwm rov ua haujlwm tshem tawm tib neeg yuam kev thaum txo sijhawm ntau lawm.Cov tshuab no muaj lub sijhawm voj voog nrawm dua, hloov cov cuab yeej ceev thiab cov khoom siv tsis siv neeg tuav kom ntseeg tau tias muaj txiaj ntsig ntau ntxiv.Cov neeg tsim khoom tuaj yeem yooj yim ua rau cov haujlwm loj hauv lub sijhawm nruj, yog li ua kom muaj txiaj ntsig zoo.

Precision engineering rau yav tom ntej innovation:

Nrog rau kev nce qib ntawm thev naus laus zis, CNC hydraulic dabtsi yog khoov tshuab kuj tseem txhim kho tas li.Kev koom ua ke ntawm kev kawm tshuab, kev txawj ntse txawj ntse thiab cov sensors siab dhau los ua rau txoj hauv kev rau kev saib xyuas thiab kev tswj hwm kev hloov pauv.Cov kev tsim kho tshiab no nce lub sijhawm ua haujlwm, qhov tseeb thiab kev ua haujlwm tag nrho, tso cai rau cov tuam ntxhab kom ua tiav qhov tsis sib xws hauv lawv cov txheej txheem hlau fabrication.Los ntawm kev lees txais cov kev nce qib no thiab nyob ntawm qhov ua ntej ntawm kev nce qib thev naus laus zis, kev lag luam tuaj yeem qhib qhov muaj peev xwm tshiab rau kev loj hlob yav tom ntej.

Hauv kev xaus:

CNC hydraulic dabtsi yog khoov tshuab tau dhau los ua cov cuab yeej tseem ceeb hauv kev lag luam hlau.Cov cav tov no muab cov precision, yoog raws, kev siv hluav taws xob thiab kev tsim khoom ntau ntxiv rau kev hloov pauv txoj kev hlau yog tsim.Raws li cov neeg tsim khoom siv zog ua ntej ntawm qhov nkhaus hauv kev lag luam hloov zuj zus, kev nqis peev hauv CNC hydraulic xovxwm nres yog qhov tseem ceeb rau kev ua kom tau zoo thiab ua haujlwm tau zoo.Siv cov thev naus laus zis no thiab saib seb nws tuaj yeem hloov pauv koj cov txheej txheem tsim khoom thiab coj koj txoj kev lag luam mus rau qhov siab tshiab.